Blog Material Applications: Wear Resistant Alloy Comparison

By: Dave Olsen

Overview

Every material selection decision includes tradeoffs. Performance can come at a price. But there is little sense in paying for capabilities that are not needed. The following suggests a framework for selecting one of a family of wear-resistant materials from another.

Comparisons

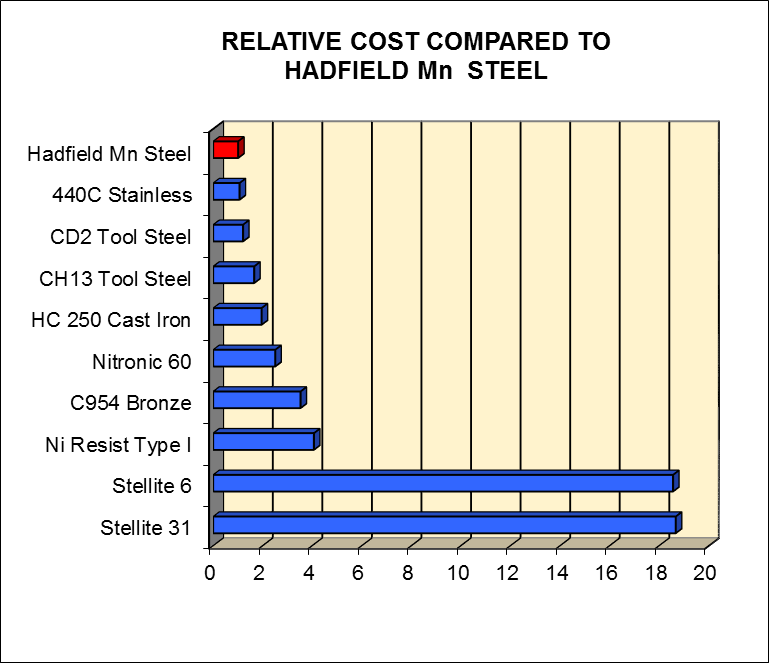

Cost

Cost is rarely ignored, so it is helpful to compare certain wear-resistant alloys as multiples of cost of a generally recognized standard material, in this case Hadfield Mn steel. This analysis attempts to capture all-in cost including processing, and not just per-pound acquisition cost.

The tradeoff, then, in material selection must reflect the possible multiples of material cost compared to the expected improvement in performance.

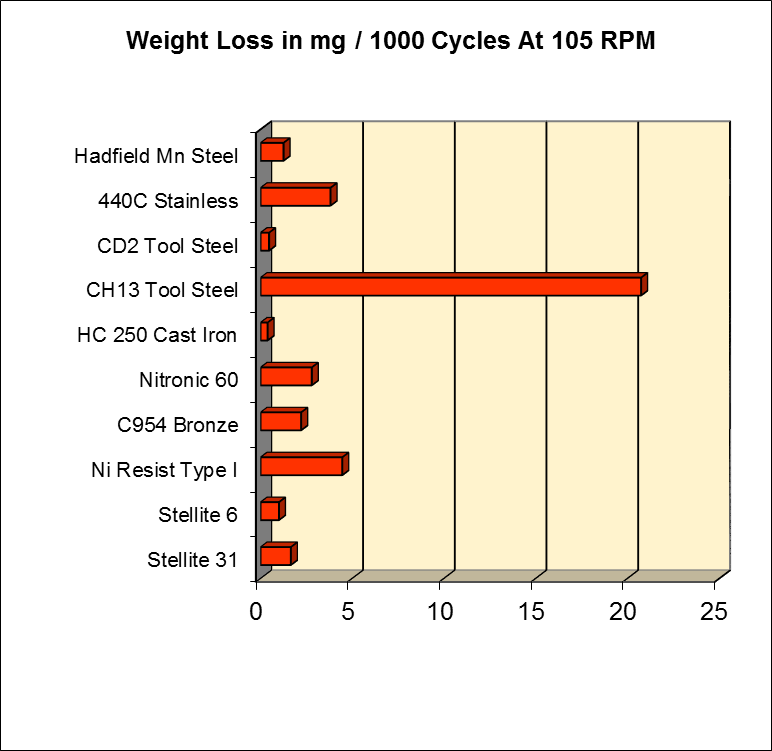

Weight Loss

A common measure of a material’s resistance to wear is how rapidly the material loses mass as it is subjected to abrasion cycles.

Presented in the same order as the cost chart above, it is easy to see which materials perform better or worse than other alternatives, as well as the cost premium that may be incurred to get that performance.

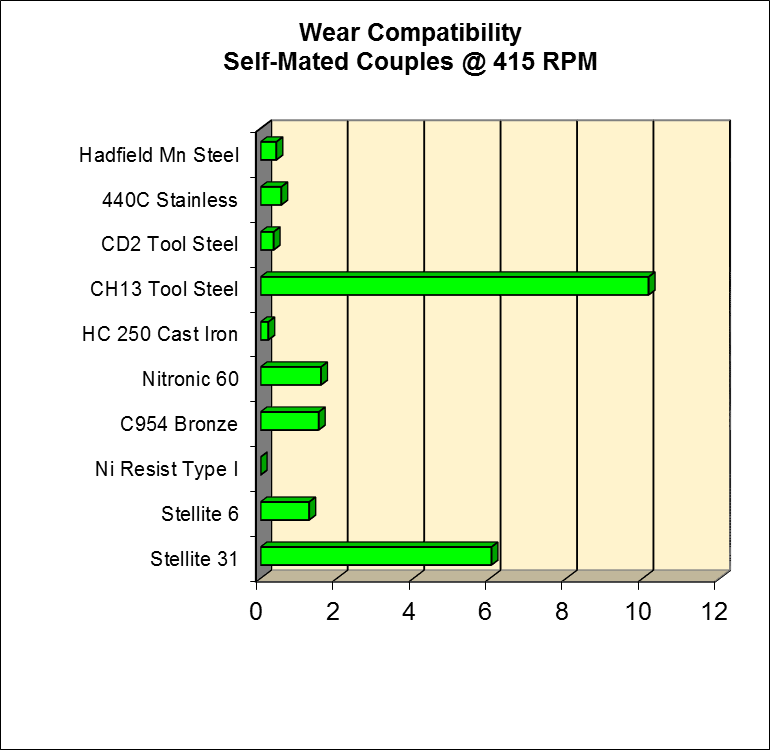

Wear Compatibility

Another measure is the amount of material lost that occurs when two components of the same material wear against each other.

Again, it is possible to visualize the different ways that materials will perform depending on the environment, specifically what the mating material is.

Conclusion

There are a number of such measures that can be used to determine the optimum material for a given application. It is equally important to consider other environmental factors that will impact performance. Is the environment corrosive? What are the expected temperatures? Is there thermal or mechanical cycling? Your Metallurgical Engineering contacts can help sort through that.